9 Easy Facts About Motorcycle Parts New Zealand Specialists Explained

Table of ContentsThe Best Strategy To Use For Motorcycle Parts New Zealand SpecialistsGetting The Motorcycle Parts New Zealand Specialists To WorkThe 9-Second Trick For Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Do?How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.Some Known Factual Statements About Motorcycle Parts New Zealand Specialists Motorcycle Parts New Zealand Specialists for BeginnersThe 25-Second Trick For Motorcycle Parts New Zealand Specialists

So, connect to one of our experts today.CNC machining modern technology is quickly becoming the focal factor of many different manufacturing procedures around the globe as a straight result of its numerous benefits over other approaches. Additionally, the industries that make bikes have actually jumped on board with this pattern. One of the most ingenious companies are currently creating their engine elements and wheels utilizing machining strategies initially developed for motorcycle components.

On the various other hand, the effects of market are the main focus of this short article. Let's obtain straight right into it. You may be wondering why we use. It is not hard to fathom the aspects that led to this result. Since we have your attention allow us discuss the reasoning behind this modern-day growth in the motorbike manufacturing market.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

Furthermore, you have complete control over the look of the components, also to the min information. Periodically, motorcyclists may choose to beautify their trip by setting up aftermarket elements or modifying the bike's remodeling. As soon as again, computer mathematical control (CNC) machining is one of the most sensible method. Upgrades might be of any kind and design you want.

3 Easy Facts About Motorcycle Parts New Zealand Specialists Described

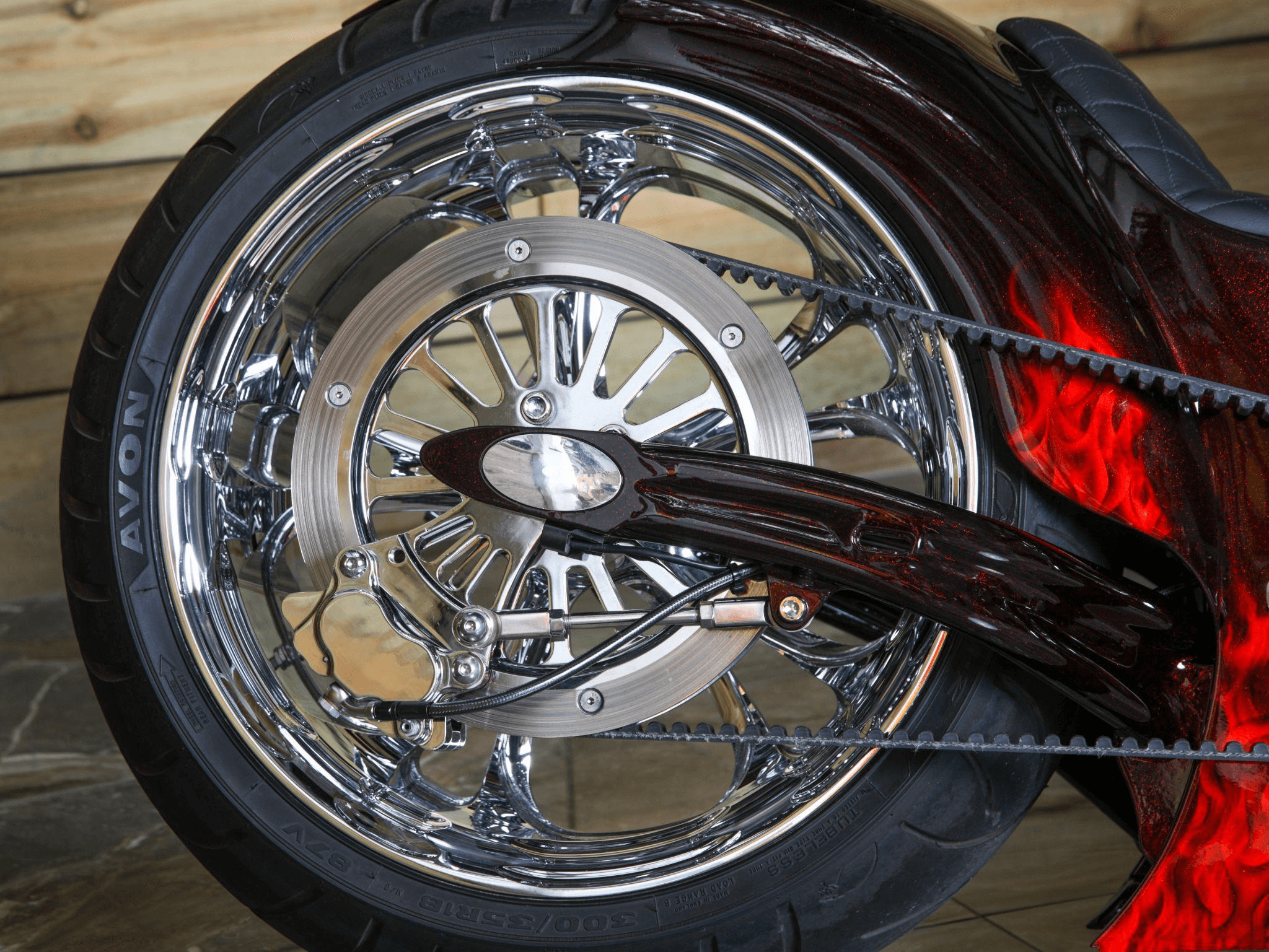

CNC machining might be made use of to make mostly all of a motorcycle's metal and plastic elements. To proceed, we'll talk about numerous machined parts for motorcycles. Unlike those on cars, wheels on bikes have a tendency to be extra apparent. Therefore, the bike's looks might be boosted with the proper personalization of these wheels.

When tailoring the wheels, the disks are where the emphasis must be. The bulk of them are made out of light weight aluminum. Light weight aluminum alloys are well-known for the impressive machining capacities that they possess. Milling procedures are utilized to obtain the desired level of wheel modification. One more element of the motorcycle that might be personalized is the tires.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

When it pertains to a vehicle (or a motorbike), one of the most important component is the engine. Several people suggest to it as the "heart" of the automobile. On the other hand, the camshaft, the cyndrical tube head, and the pistons tend to be intricate and call for layouts with a high level of accuracy.

Lighting is one more facility facet of customization. Use only high-quality items, nevertheless, since these lights are critical for the safety of motorcyclists and other chauffeurs or people when traveling, specifically in the evening. Motorcycle headlights have three main parts: the bulb, or light, the lens, and the housing. Particularly, we customize the lens and the real estate.

Milling procedures with a remarkable coating would result in the lenses having a reflective high quality that is comparable to that of a mirror. The cover, on the other hand, is not composed of vulnerable materials; rather, it is built out of tough polymers that can be machined right into even more intricate patterns.

Unknown Facts About Motorcycle Parts New Zealand Specialists

Motorbike producers commonly cast these elements, yet just for the production of bespoke parts. Machining on five axes in today's globe is the ways by which any layout form may be understood.

The success of the procedure is contingent on the mill cutters' ability to calculate subtle and complicated angles accurately. Select Runsom for your tailored bike parts! We have the capacity to fabricate difficult and trendy components making your motorcycle matchless. Many are crafted from aluminum or steel alloys, each of which has its uses and benefits.

Right here are a couple of instances of metals often made use of in bike component machining. Aluminum is the primary material utilized by business specializing in generating custom motorcycle elements to produce many of these components - Motorcycle Parts New Zealand Specialists.

Zinc describes an additional steel that is extremely light in weight and has fantastic machining high qualities because of its high mechanical toughness. This material may be developed right into virtually any shape and maintains its dimensions well. Even mission-critical components that need a high level of accuracy may take advantage of their use.

See This Report on Motorcycle Parts New Zealand Specialists

One check my blog more steel that sees heavy use in the production of CNC-customized parts is magnesium. It is among the lightest steels that are now obtainable and has exceptional machinability attributes and strength compatible with its low weight. One of the disadvantages of magnesium is that its dust may conveniently ignite.

As a result of its remarkable machinability and weldability, stainless-steel is an alloy that is especially well-suited for CNC processes. In enhancement to this, they have wonderful rust resistance and a high aesthetic appeal. Their most typical use in creating different motorbike components is fasteners, such as screws and bolts. Their low sensitivity to oxidation and corrosion makes them ideal for this usage.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

It appears that CNC transforming and grating are the foundational processes. Different methods exist, such as boring. Let's examine a number of these machining More Help strategies in deepness. The CNC turning technique is taken into consideration a subtractive production technique. Furthermore, it needs keeping bars of material, most often plastic or metal, ready and then turning a cutting device to get rid of sections of the material as the material is transformed.

These approaches are equally essential and create elements with high precision and consistent quality. The processes assist boost the general quality of the machined motorcycle components.

Facts About Motorcycle Parts New Zealand Specialists Revealed